01Characteristics of TAZMO's ultra precise slit coater

User friendly precise slit nozzle

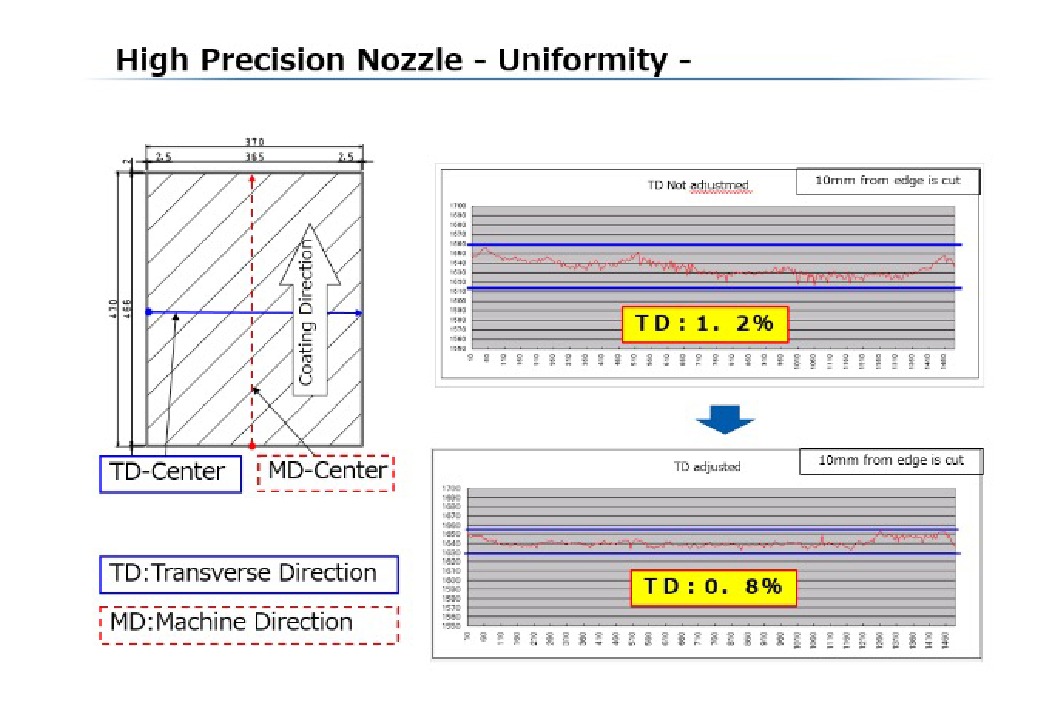

- Excellent thickness uniformity

- Easy maintenance. After dismantling and cleaning the slit nozzle, you can easily assemble it with precision maintained. Super easy.

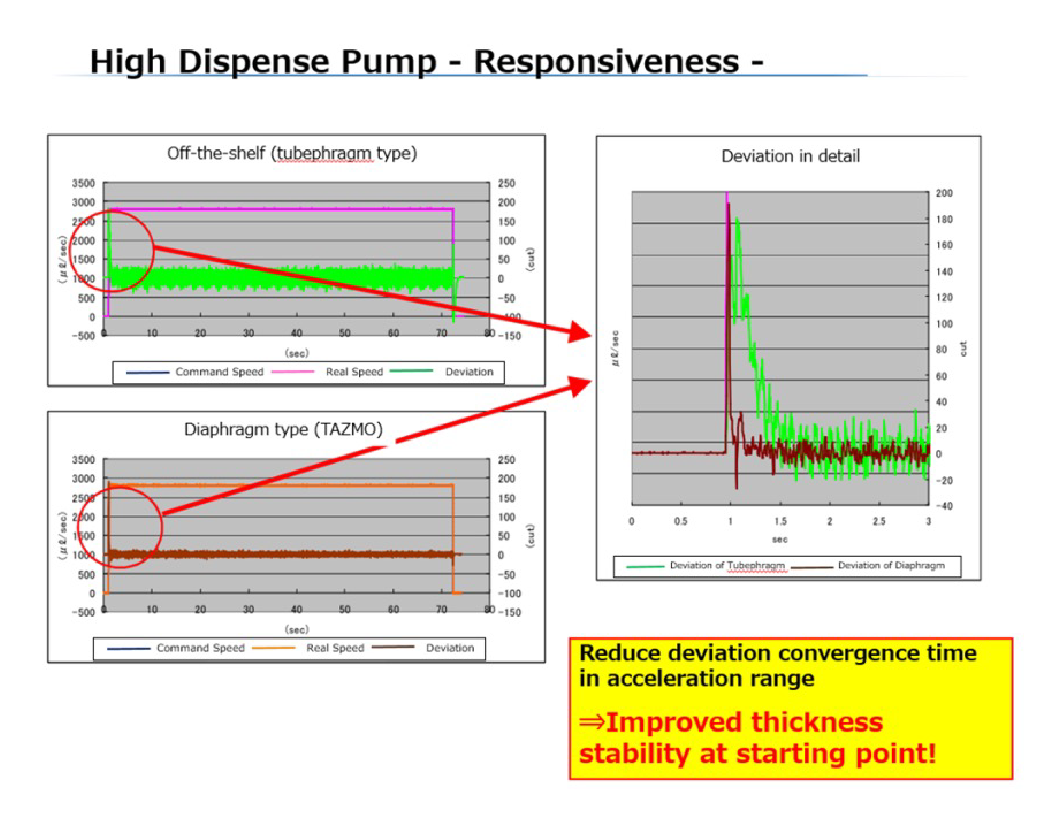

High performance metering discharge pump

Better thickness control from the beginning.

Air Floating Mechanism

Reduces chance of damage to substrate and eliminates static discharge

02Comparison with other coating methods and still coater

| Coating Method | Slit coater | Ink jet | Spin coater |

|---|---|---|---|

| Coating principal |

Coating material is discharged from a narrow gap between rigid and very precise dies. Thickness of coating material can be highly uniform. |

Droplets of coating materials are applied to the object to be coated. Small amounts of coating materials can be coated. Precise pattern coating is possible. | The coating material is poured on the upper surface of the object to be coated and the coated object is rotated at high speed. Coating film is formed by centrifugal forces. |

| Illustration |  |

|

|

| Merit | ① Small amount of coating material loss. ② Thickness of coating material can highly be uniform. |

① High film thickness uniformity ② High-precision narrow frame functional film can be applied ③ High-precision landing and separate coating are possible ④ Material loss can be minimal. |

① Thin and uniform coated films can be obtained. ② Simple mechanism |

| Demerit | ー | ー |

① Material loss ② This method can be used only on flat surfaces |

- Slit coater

- Coating principal

Coating material is discharged from a narrow gap between rigid and very precise dies.

Thickness of coating material can be highly uniform. -

Illustration

-

Merit

①Small amount of coating material loss.

②Thickness of coating material can highly be uniform. - Demerit -

- Ink jet

- Coating principal Droplets of coating materials are applied to the object to be coated. Small amounts of coating materials can be coated. Precise pattern coating is possible.

-

Illustration

- Merit ①High film thickness uniformity ②High-precision narrow frame functional film can be applied ③High-precision landing and separate coating are possible ④Material loss can be minimal.

- Demerit -

- Spin coater

- Coating principal The coating material is poured on the upper surface of the object to be coated and the coated object is rotated at high speed. Coating film is formed by centrifugal forces.

- Illustration

- Merit

①HThin and uniform coated films can be obtained.

②Simple mechanism - Demerit

①Material loss

②This method can be used only on flat surfaces

03Evolution of Slit Coaters

TAZMO has been collaborating with several institutes and customers to create new technologies related to slit coaters. The followings are examples of the joint developments.

Slit Coater with heater

Heating nozzle, route of ink, pump and substrate enabled to coat diffcult-to-dissolve material.

One of the applications of this technology is to coat organic semiconductors to flexible panels, while it is crystalized at the nozzle of the coater with a heating function.

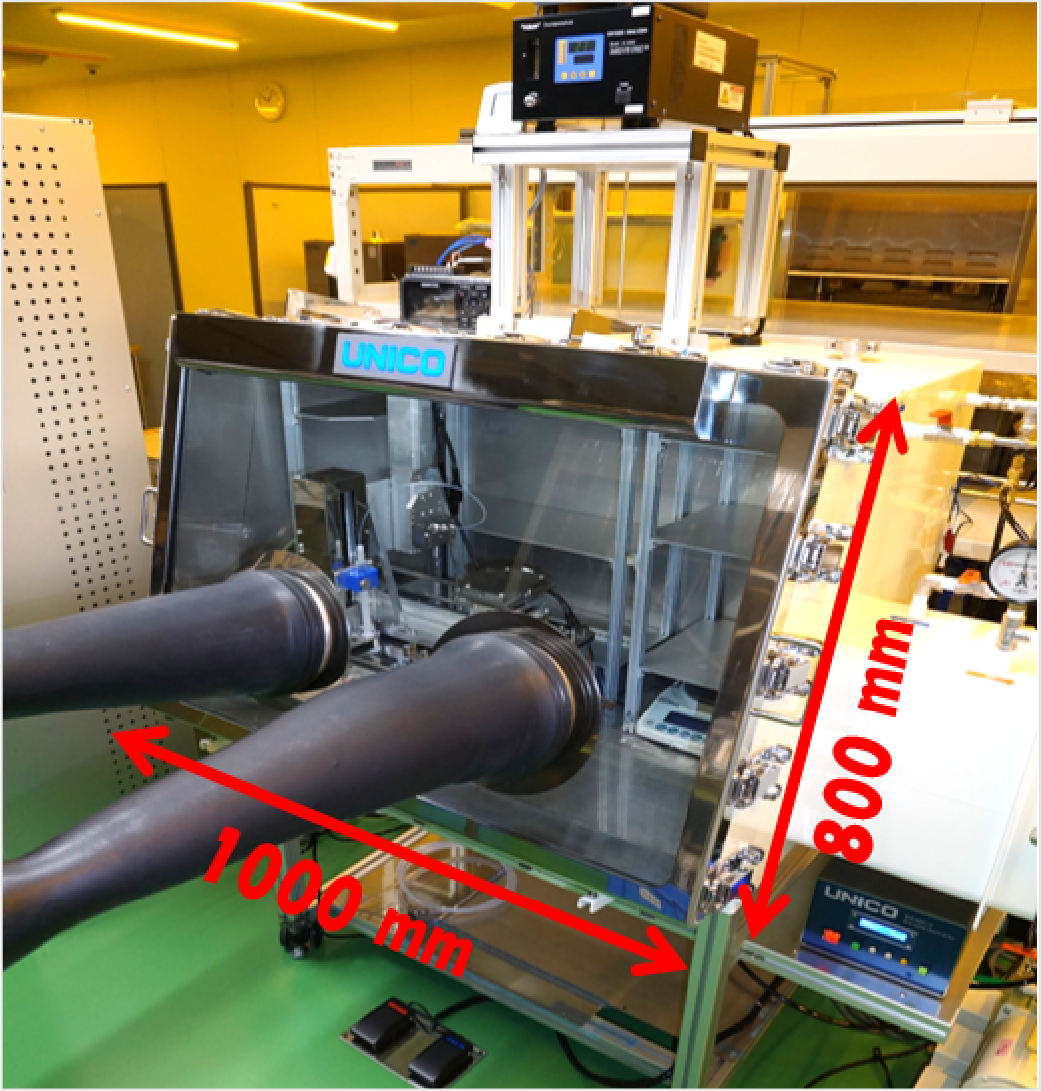

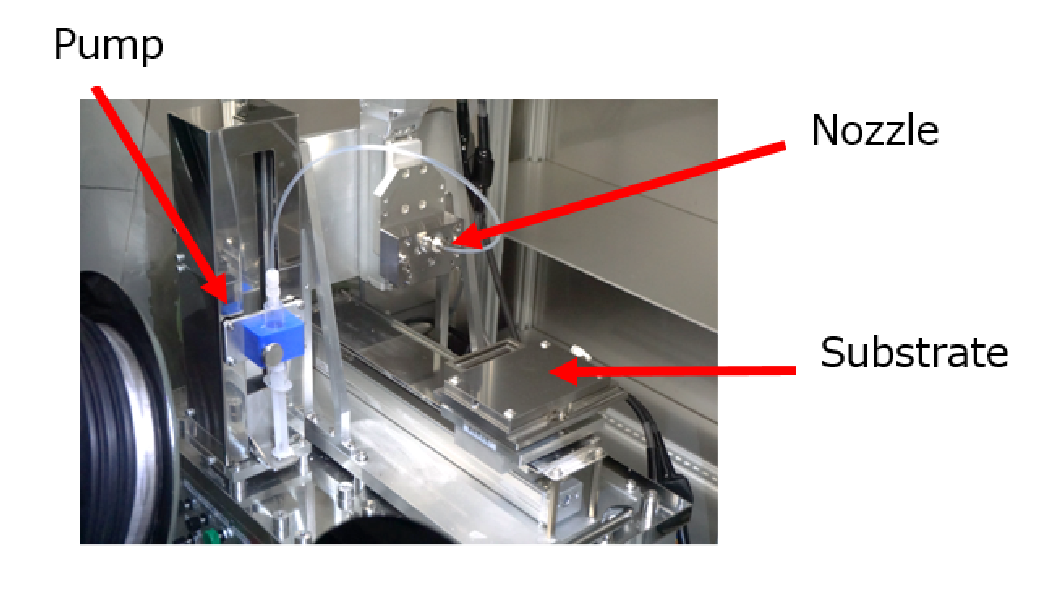

Compact Slit Coater for R & D

HTazmo has developed a compact system which can be installed inside of a small enclosure.

| Coating width | 50mm |

|---|---|

| Coating length | 75mm |

| Substrate size | 80 mm x 97 mm |

| Transfer speed | Up to 50mm/s |

| Uniformity | Less than 10% |

| Dew point | Maintain less than - 80 Degree |